1. Stovall Foundation Systems

📍 Cape Coral, Florida

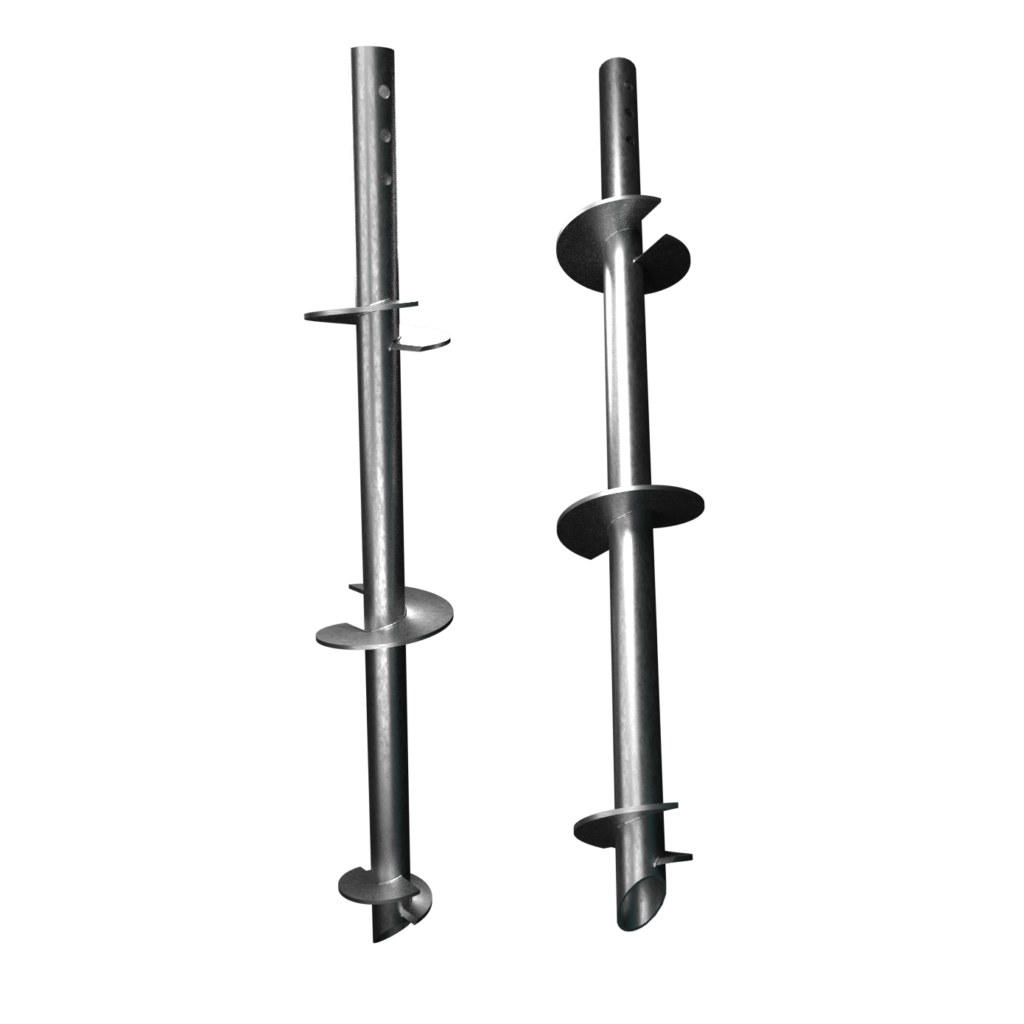

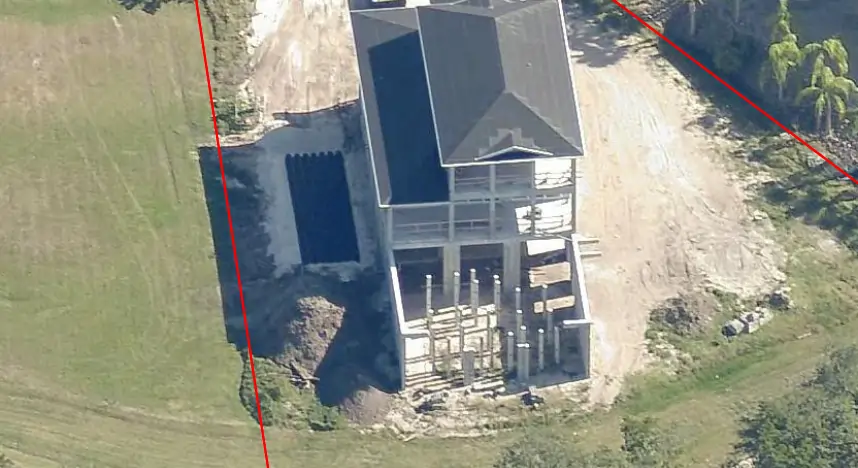

Stovall Foundation Systems specializes in pile driving and helical piling installation for deep foundation support. They provide high-quality driven and helical piles for residential, commercial, and industrial projects. Their expertise ensures strong, stable foundations in various soil conditions.

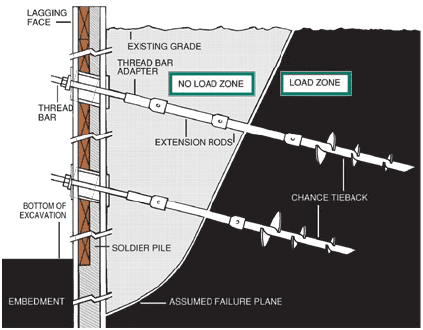

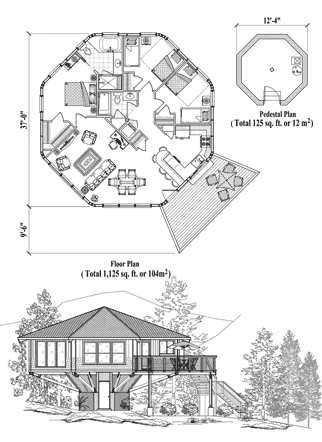

Helical piles are an excellent choice for light to mid-weight structures, offering fast installation with minimal disturbance. Meanwhile, driven piles provide superior load-bearing capacity for heavier structures. Stovall uses advanced equipment to install both systems efficiently, ensuring long-term stability.

With a commitment to precision and strength, Stovall Foundation Systems remains a top choice for foundation solutions in Florida. Contact us today to discuss your project and find the best piling option for your needs!

2. US Helicals

📍 Orlando, FL

US Helicals installs helical piers and screw piles for foundation support. They work on both commercial and residential projects. Their services ensure strong and stable foundations.

3. Helicon

📍 Orlando, FL

Helicon offers helical piers, concrete lifting, and seawall repair. They serve the greater Orlando and Tampa areas. Their solutions improve foundation stability in different soil conditions.

4. Florida Foundation Systems Inc.

📍 Pompano Beach, FL

Florida Foundation Systems provides helical piles for new construction and remodeling projects. Their team helps ensure structures remain secure in weak soil conditions.

5. Foundation Masters, LLC

📍 Tampa, FL

Foundation Masters designs and manufactures helical piers for various applications. They also offer foundation repair solutions with a lifetime warranty.

6. Coastal Foundation Solutions

📍 Naples, FL

Coastal Foundation Solutions specializes in helical piling for residential, commercial, and industrial projects. They help stabilize structures in challenging environments.

Stovall Foundation Systems leads the list as a reliable pile driving contractor. While they focus on driven piles, the other companies specialize in helical piling. If you need a foundation expert, consider these professionals. Contact them to discuss your project and get a quote.