Helical Tieback Overview

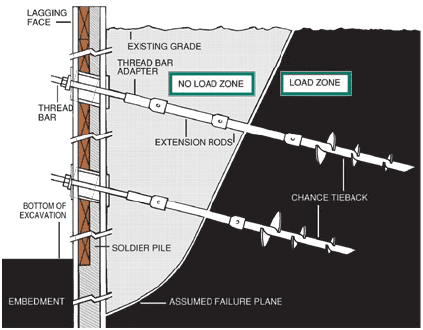

A helical tieback is a deep foundation system that provides lateral support for earth retention and retaining wall applications. It consists of a steel shaft with helical plates welded at precise intervals. Contractors install the tieback by rotating it into the soil, which creates resistance against lateral earth pressures and improves structural stability. As a result, helical tiebacks effectively secure structures against shifting and failure.

Applications

Helical tiebacks are commonly used to reinforce:

- Basement walls

- Slopes

- Seawalls

- Temporary and permanent shoring

Because of their compact design, helical tiebacks can be installed in tight spaces, making them ideal for urban projects. Unlike traditional anchoring methods, they require minimal excavation and eliminate the need for grouting. Therefore, they provide a cleaner, faster, and more efficient solution for stabilizing structures.

Design & Load Capacity

Several factors determine a helical tieback’s capacity, including:

- Soil conditions

- Shaft diameter

- Number and size of helices

To ensure optimal performance, engineers design tiebacks based on specific project requirements. Moreover, installation torque provides real-time verification of load-bearing capacity, ensuring compliance with engineering standards. In addition, load testing further confirms performance under expected conditions, offering greater reliability.

Installation Advantages

Helical tiebacks offer several key advantages over traditional anchoring methods.

- Minimal site disturbance: Since lightweight equipment is used, mobilization costs are significantly reduced.

- Quick installation: Because no curing time is required, helical tiebacks allow for immediate loading, accelerating project timelines.

- Versatility: They perform well in weak or loose soils, making them suitable for a wide range of geotechnical applications.

Durability & Adjustability

Furthermore, helical tiebacks are designed for long-term performance.

- Galvanization or epoxy coatings protect against corrosion, ensuring extended durability.

- Tiebacks can be adjusted, re-tensioned, or removed as needed to accommodate future structural modifications.

Conclusion

In summary, helical tiebacks provide a cost-effective, efficient, and environmentally friendly solution for lateral stability. Their adaptability, rapid installation, and reliable performance make them a preferred choice for geotechnical and structural applications. Consequently, engineers and contractors increasingly rely on them to meet the demands of modern construction projects.